The Invention of Steel – Where and When did it Happen?

The history of steelmaking in Australia began in 1840 when iron ore deposits were discovered in South Australia. However, the ore was not of high quality, and the production techniques were not efficient enough to enable mass production. This meant that almost all of Australia’s steel was imported by the start of the 20th century.

The situation has changed since then. The first blast furnace in the country was established in 1901, by William Stafford. Further steelworks were then created, in Newcastle, Port Kembla, and Whyalla.

Today, a significant amount of the country’s steel is still imported but there are several high-quality steel suppliers in Australia. While this history of Australian steel is relatively short, the world history of the metal alloy is a lot longer.

Key points

- Steel production techniques happened as far back as the Iron Ag

- In the 6th century BC craftsmen in India created an alloy known as Wootz steel

- Karl Wilhelm Siemens developed the Open Hearth Process in the 19th century with steel produced in big shallow furnaces

- Paul Heroult created the electric arc furnace (EAF) which works by passing an electric current through charged material

Need a Quote?

RECOMMENDED ARTICLE

Cold Formed Sections in Building Industries – Entegra Signature Structures

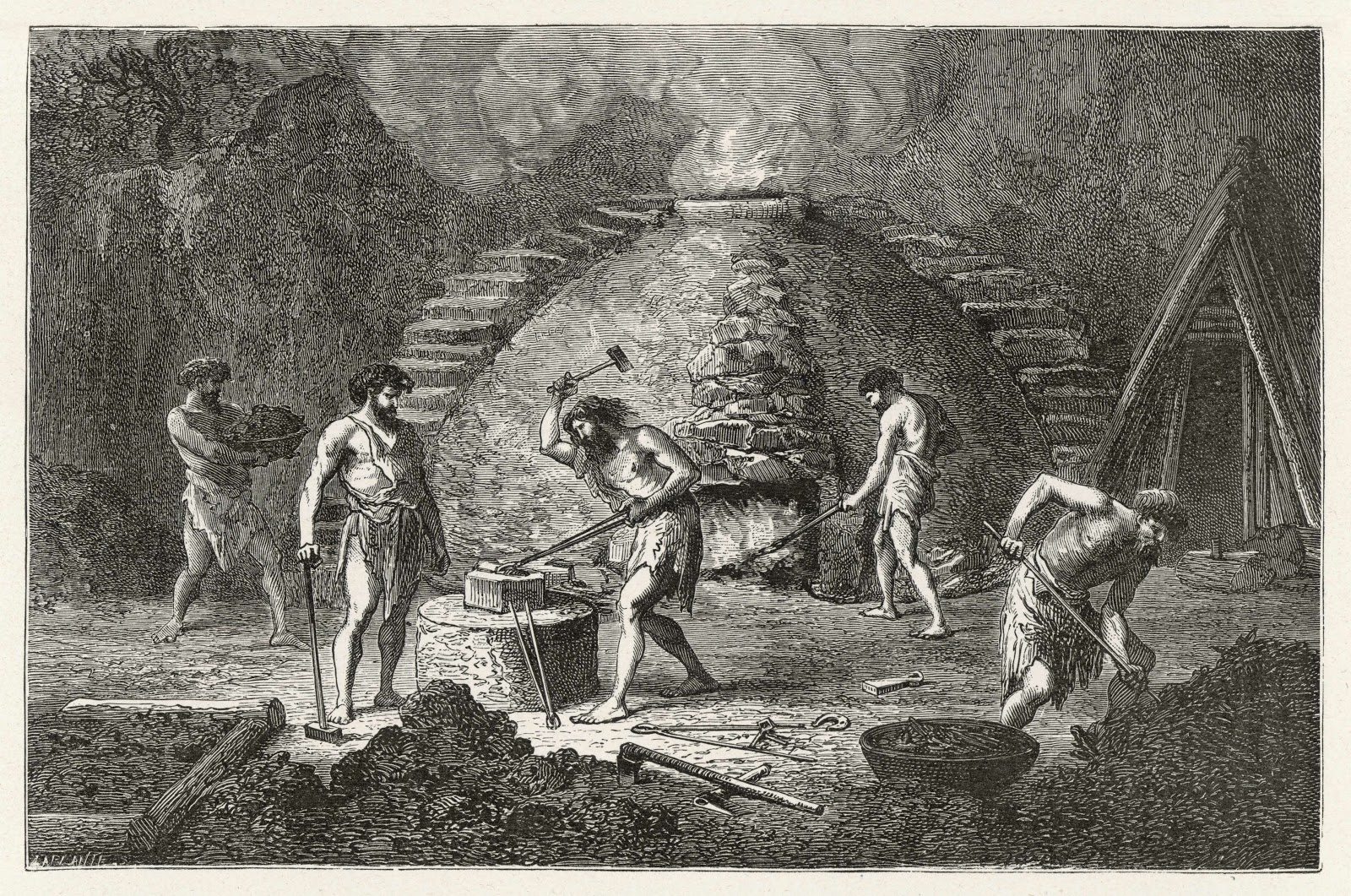

The early invention of steel making techniques

The early days of steel production techniques happened as far back as the Iron Age. Although, this was not the type of steel that we think of today and may have been closer to cast iron. It was however the first time that carbon was added to iron to create a stronger metal that was similar to modern-day steel.

It’s unclear where the first use of these techniques happened but it is known that in the 6th century BC craftsmen in India created an alloy known as Wootz steel. By the 3rd century AD, China was mass producing an early type of steel. The exact techniques used are not known but they were likely to have been similar to the more modern Bessemer Process.

The earliest example of the rust-resistant early steel that still survives today is The Iron Pillar of Delhi which was created around 402 AD. Another step in the early days of steel happened in the 11th century when Damascus Steel was created in the Middle East. This mysterious metal alloy is the inspiration behind the Valyrian Steel in Game of Thrones. It was to be several hundred more years before the modern history of steel began.

RECOMMENDED ARTICLE

Grape byproducts open new markets – Entegra Signature Structures

Blister steel and the Crucible Steel Technique

Blister steel is one of the earliest types of modern-day steel. Germany and England began production in the 17th century. They increased the amount of carbon in molten pig iron and used a process called cementation.

The process advanced further when Englishman Benjamin Huntsman invented the modern crucible steel technique. Several other advancements followed, during the 17th century and the 18th century, as the Industrial Revolution started including the power of steam and the creation of the steel roller by Henry Cort.

The Bessemer Process

The next big steel invention happening took place in 1856 when Henry Bessemer created what became known as the Bessemer Process. This involved blowing oxygen through molten iron in order to reduce carbon content. The process could be completed quickly and was not expensive.

However, initially the process removed too much carbon and left too much oxygen. Bessemer resolved the problem when he added the newly created compound spiegeleisen to the process. Sidney Gilchrist Thomas improved the Bessemer Process further, in 1876, by adding limestone to remove phosphorus from the pig iron.

The Open Hearth Process

German engineer Karl Wilhelm Siemens developed another steel making process during the 19th century. This became known as the Open Hearth Process as the steel was produced in big shallow furnaces. This method meant that steel could be produced in larger quantities as it overcame the problem of insufficient temperature that traditional furnaces had. This led to the Open Hearth Process largely taking over from the Bessemer Process by 1900.

Electric Arc Furnace Steelmaking

By the early 20th century, steel making had come a long way from its early origins, thanks to the efforts of creative minds like Bessemer and Siemens. Now it was Paul Heroult’s turn to make a difference. He created the electric arc furnace (EAF) which works by passing an electric current through charged material.

The process was initially used to make specialty steel, but it was adopted for wider use during World War II. Since then, companies across the world have adopted this steel making process.

Oxygen Steelmaking

Although the EAF process is still in use today it’s not the most widely used steelmaking process in the global steel industry..That accolade belongs to Oxygen steelmaking. This process involves blowing oxygen into large amounts of molten iron and scrap steel.

This can be done quickly. It takes around one hour to convert 350 metric tons of iron to steel. Given the efficiency of this type of steelmaking, it’s little wonder that it accounts for over 60% of the global industry.

The Australian steel history may be relatively short, but the invention of steel internationally happened many centuries ago. We may not know the names of the people who created early steel, but the visionaries mentioned in this article invented the techniques and processes that brought us to the steel that we know today.

RELATED ARTICLES

Australian Sourced v Australian Made – Entegra Signature Structures

The Most Innovative Factories Making Their Mark on the World – Entegra Signature Structures

How Robotics and Automation will Change Australian Businesses – Entegra Signature Structures

https://steelfabservices.com.au/who-invented-steel-a-look-at-the-timeline-of-steel-production/

https://www.popularmechanics.com/technology/infrastructure/a20722505/history-of-steel/

https://www.britannica.com/technology/steel/Forming-and-casting

https://www.thoughtco.com/a-short-history-of-steel-part-ii-2340103

https://www.hardbakka.com.au/steel-manufacturing-australia-brief-history/

2 - 2Shares