Design and Engineering Feats

Australian Patented Technology

Entegra invests heavily in research and development to enhance our manufacturing capability for complex engineering tasks. We’re an expert in the sectors we partner with because we gain exclusive access to training, important events and major conferences related to the area of practice. We’ve patented technology, most notably with our RidgebackTM and triangular trusses.

Our award winning capability is without peer in Australia, with our design, engineering and manufacturing teams under one roof.

Clear-Span Buildings

Eliminating central posts have been a desirable outcome for retail buildings but not achieved often due to prohibitive costs. Entegra is a large span specialist pioneering the first 50m clear span in 1997. We have stretched the boundaries yet again to produce a record 80m clear-span Horticulture Packing shed in the Yarra Valley in 2019.

Environmentally sound

“Passive Box”

Structures – we design and engineer all our building to maximise solar loading to produce between 650kW and 1000kW on a roof space of 10000sqm. Furthermore they are designed to harvest 100% of the rainfall that can be collected harvested for various uses.

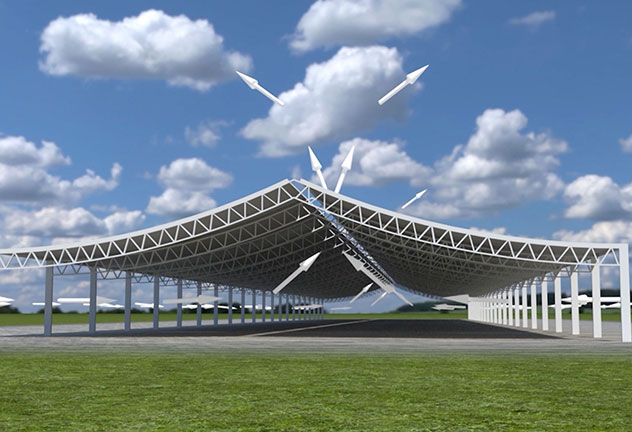

Roof-Lift Technology

Entegra pioneered roof-lift methodology in 1991 to cut the build time of steel structures to a fraction of the time the traditional stick-build methods take. The structure is built on the ground and lifted using cranes. A 15000sqm structure was lifted in two lifts during a single day in Mildura recently.

Patented Technology

We have a strong commitment to finding solutions for clients. We have patented multiple innovative designs.

High Volume Tapered gutter systems

Entegra has a patented gutter system used for dairy, feedlot and agricultural buildings. The gutter systems operate without restriction on the flow from the end of the gutter into the rain head – traditional gutters have a downpipe in the base of the gutter that the water has to find it’s way into which restricts the natural flow of the water. In the case of the high volume Taperflow™ it is completely open and which allows the water to maintain its natural flow into the rain head. The large rain head allows the water to build up a head of pressure and whirlpool into the single downpipe. The tapered system increases in size as it approaches the rain head on one end of the shed.